Inquire Now

Real Time Information

Columnar

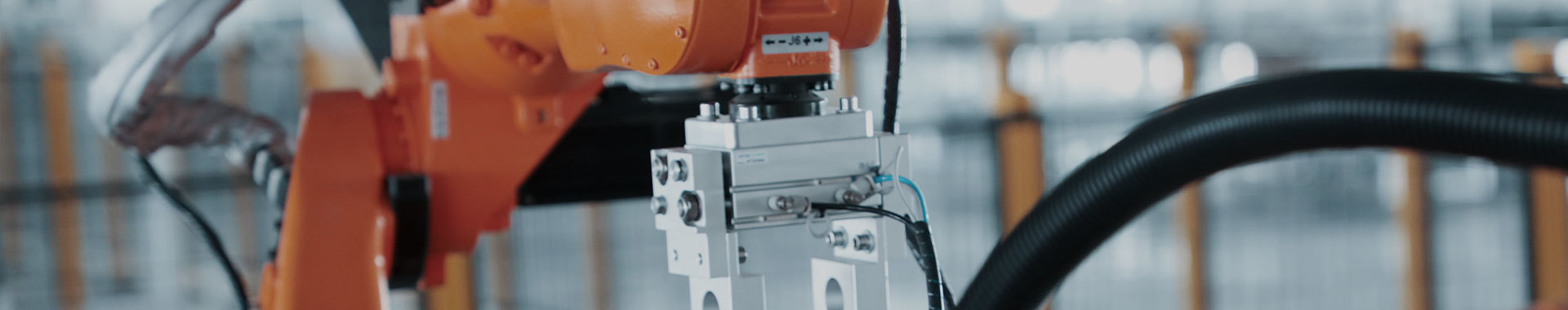

Applying the principle of balance of forces, the operator is able to move and position the weight in space in a balanced manner by pushing and pulling it accordingly. The weight forms a floating state when lifted or lowered. No skilled pointing operation is required, the operator pushes and pulls the weight by hand to place it correctly in the designated position. 1. Structure: The fully pneumatic assisted manipulator is mainly composed of a mounting base, a mainframe and a fixture. 2. The mounting base is divided into: 1. column fixed type 2. base mobile type 3. canopy suspension fixed type 4. canopy suspension mobile type; 3. fixture: generally according to the external dimensions of the workpiece provided by the customer to Customized. Fixtures are generally 1. hook type; 2.

Classification:

Columnar

Keywords:

Column fixed type

Assisted robots

Smart Lifter

- 产品描述

-

- Commodity name: Columnar

- Commodity ID: 1122483191676555264

Applying the principle of balance of forces, the operator is able to move and position the weight in space in a balanced manner by pushing and pulling it accordingly. The weight forms a floating state when lifted or lowered. No skilled pointing operation is required, the operator pushes and pulls the weight by hand to place it correctly in the designated position. 1. Structure: The fully pneumatic assisted manipulator is mainly composed of a mounting base, a mainframe and a fixture. 2. The mounting base is divided into: 1. column fixed type 2. base mobile type 3. canopy suspension fixed type 4. canopy suspension mobile type; 3. fixture: generally according to the external dimensions of the workpiece provided by the customer to Customized. Fixtures are generally 1. hook type; 2.

Applying the principle of balance of forces, the operator is able to move and position the weight in space in a balanced manner by pushing and pulling it accordingly. The weight forms a floating state when lifted or lowered. No skilled pointing operation is required, the operator pushes and pulls the weight by hand to place the weight correctly in the designated position.

1. Structure: The fully pneumatic assisted manipulator mainly consists of a mounting base, mainframe and fixture.

2. mounting base is divided into: 1. column fixed type 2. base mobile type 3. roof suspension fixed type 4. roof suspension mobile type;

3. Fixture: generally according to the customer to provide the shape of the workpiece to customize the size. The fixture generally has 1. hook type; 2. gripping type; 3. clamping type; 4. internal rise type; 5. lifting type; 6. clamping type; 7. clamping flip type (flip 90° or 180°); 8. vacuum adsorption; 9. vacuum adsorption flip type (flip 90° or 180°) and other ways, according to the specific workpiece and the environment to choose and R & D design, has achieved the best use effect.

4. mainframe: mainly composed of balancing cylinder and rigid multi-clamp cantilever, the main parameters are lifting capacity and service radius.Model Working air pressure

(bar)

Maximum service radius (m) Maximum lifting capacity

(Kg)

Max. lifting stroke (m) HJZL-50

5

2.5

50

2

HJZL-75

5

2.5

75

2

HJZL-100

5

2.5

100

2

HJZL-125

5

2.5

125

2

HJZL-150

5

2.5

150

2

HJZL-175

5

2.5

175

1.5

HJZL-200

5

2.5

200

1.5

HJZL-250

5

2.5

250

1.5

HJZL-300

5

2.5

300

1.5

HJZL-400

5

2.5

400

1.5

HJZL-500

5

2.5

500

1.5

Working radius and lifting stroke can be set according to workpiece size and site requirements Principle: Real-time balancing of workpieces within a certain weight range is achieved by fast and precise adjustment of the air pressure in the balancing cylinder. Depending on the weight of the workpiece to be lifted, the smallest model should be selected to match the maximum workpiece weight. Each unit is equipped with an air storage tank, which can be used for one cycle in case of a loss of air, with an alarm to remind the operator (this function is optional) and a self-locking function to prevent the workpiece from falling when the air pressure drops to a certain level. A safety system is also provided so that the operator cannot release the workpiece during handling or if the workpiece is not placed on a safe surface. In combination with various non-standard fixtures, the manipulator can lift workpieces of various shapes.